Best Plastic Mould Manufacturers in Ekkaduthangal | High-Quality Moulding Solutions

Looking for reliable plastic mould manufacturers in Ekkaduthangal? At Itech Moulds, Ekkaduthangalgets high-quality, precision-engineered plastic moulds for automotive, construction, and industrial applications. Contact us for customized moulding solutions today!

Plastic Mould Manufacturers in Ekkaduthangal – Quality Moulding Solutions for Diverse Industries

Ekkaduthangal is a hub for industrial manufacturing, with a growing demand for high-quality plastic moulds in various sectors. Whether you require plastic moulds for automotive, construction, medical, or general engineering applications, Ekkaduthangal is home to some of the best plastic mould manufacturers. These manufacturers provide precision-engineered moulds tailored to meet industry standards and specific customer needs.

Why Choose I Tech Moulds for Plastic Moulds Manufacturers in Ekkaduthangal?

Plastic moulds play a crucial role in shaping plastic components used across various industries. They are designed to create products with high durability, flexibility, and resistance to wear and tear. Some of the key benefits of plastic moulds include:

- High Precision: Plastic moulds ensure accurate dimensions and detailed designs.

- Durability: These moulds are made from high-quality materials to withstand repeated use.

- Cost-Effectiveness: Plastic moulding reduces material wastage and speeds up production.

- Versatility: Plastic moulds can be customized for different applications, including industrial, commercial, and household products.

Industries Served by I Tech Moulds in Ekkaduthangal

Leading plastic mould manufacturers in Ekkaduthangal cater to a wide range of industries, including:

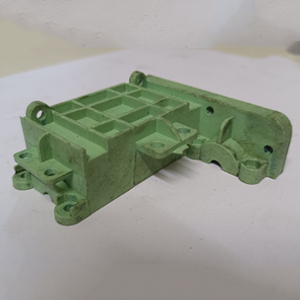

Automobile Industry

- Manufacturing of plastic seals, gaskets, and engine components.

- Custom plastic moulds for vehicle parts and accessories.

Construction Industry

- Plastic moulds for concrete blocks, paver blocks, and tiles.

- Moulds designed for durability and repeated use in construction projects.

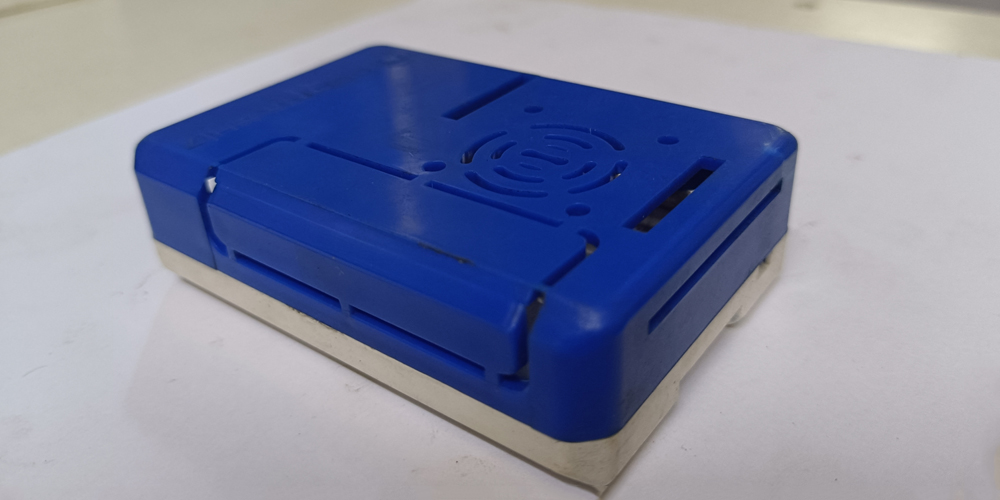

Electrical and Electronics

- Insulated plastic components for wiring and electrical fittings.

- High-precision plastic moulds for electronic enclosures.

Medical and Healthcare

- Medical-grade plastic moulds for healthcare equipment and devices.

- Custom moulds for surgical and laboratory applications.

Household and Consumer Goods

- Plastic moulds for kitchenware, toys, and utility items.

- Moulding solutions for customized product manufacturing.

Types of Plastic Moulds Available at I Tech Moulds, Ekkaduthangal

Plastic mould manufacturers in Ekkaduthangal offer a wide variety of moulds, including: